Semi-Finalists

Solutions to prevent plastic microfiber pollution by transforming our clothing & textiles.

Werewool fibers are created by programming microorganisms to biosynthesize proteins with specific structures that mimic aesthetic and performance properties found in nature.

Biophilica aims to disrupt the 7,000-year-old leather industry with their new plant-based alternative, Treekind™.

A team of entrepreneurs, academics, designers and students at MIT has developed a new material using smart polyethylene-based fibers that they believe can shake up the fashion industry while also protecting waterways.

Squitex has developed a unique protein structure originally found in the tentacles of the squid.

Spinnova mechanically refines wood or waste into a textile fiber without any harmful chemicals in the manufacturing process.

Slow Factory, a New York-based team has developed a natural, biodegradable leather alternative that is produced in a similar way to kombucha.

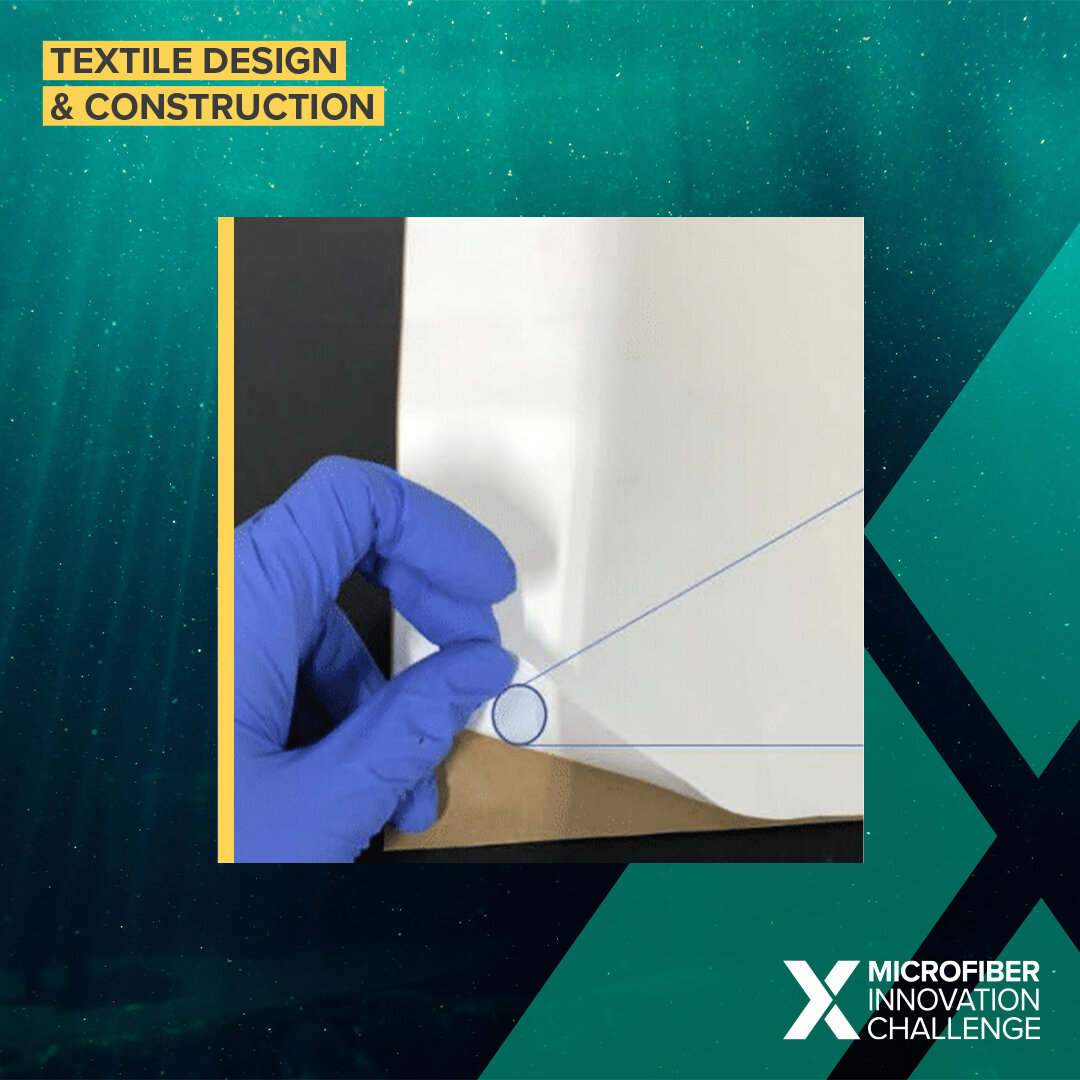

Dimpora believes that their biodegradable membrane will soon be used to produce sustainable, comfortable and high-performance outdoor wear across the world.

The team behind Nanofique are preventing microfiber pollution created by the washing and dyeing process in textile factories with their unique filtration system.

Polystyrene, the material used in Styrofoam coffee cups, may soon be turned into clothing thanks to a team based at Ohio University.

Piñayarn converts pineapple leaf fiber into a commercially-viable material that can be used as yarns for knitted and woven textiles.

PANGAIA and MTIX have teamed up to develop a novel application of MTIX's multiplexed laser surface enhancement (MLSE®) technology to modify the surfaces of fibers within a fabric in such a way that prevents microfiber shedding.

Orange Fiber has patented an innovative process that creates sustainable fabrics from the by-products of citrus juice.

Natural Fiber Welding uses a patented closed loop, green chemistry platform to engineer precise hydrogen bonding networks in yarns composed of natural fibers.

Mango Materials has developed an innovative manufacturing technology that turns waste carbon emissions into biodegradable biopolyester fibers.

CSIRO's yarn structure design for cotton and polyester reinforces the structural integrity of yarns and thereby significantly reduces microfiber pollution.

Kintra Fibers develops bio-based and compostable synthetic yarns derived from sugar instead of petroleum.

The Cellugy team is producing nanocellulose through sugar fermentation as a coating for textiles to enable recycling and prevent plastic microfiber shedding.

London-based Nanoloom is creating a solution to microfiber pollution by repurposing an innovation initially designed for wound healing.

Dipole Materials are creating the next generation of sustainable, microfiber-free textiles through their innovative electrospinning development process.

This team believes that SCOBY leather will soon be making its way to jackets, car seats, sofas, purses, wallets etc.

FreyZein uses regenerative fibers to develop natural textiles without compromising performance

The Citizen Earth Group is using agricultural waste from bananas to develop a new material that has a low carbon footprint.

AltMat is developing new manufacturing methods that repurpose agricultural waste into environmentally-friendly, valuable products.

AlgiKnit is creating eco-conscious, renewable yarns derived from a seaweed called kelp, one of the most regenerative organisms on the planet.